High Temperature Furnaces

High Temperature Furnaces

A high-temperature furnace, also called an industrial furnace, is a type of laboratory furnace that reaches higher temperatures than a typical furnace. Ideal for many uses, high-temp furnaces contain radiant heating elements within a heat chamber to produce excellent temperature control with reliable temperature uniformity.

- Max working temperature: 1500°C to 1800°C

- 208/220V single phase for all the model Excellent temperature uniformity

- Control heating rates, dwells (time holds), and cooling rates with 30-segment easy-to-use PID programmable temperature controller Long-lasting high-temperature Silicon Carbide heating elements ensure the longest heating element life, best heat radiation properties at high temperatures, and easy exchange

- Long-lasting high-temperature Silicon Carbide heating elements ensure the longest heating element life, best heat radiation properties at high temperatures, and easy exchange

- Ceramic fiber board lining ensures energy efficiency

1500°C Degree Celsius High-Temperature Box Furnace (2730°F)

1500°C Box Furnace Features Check out some of the previously custom built box furnaces below. Interested in getting additional details? Contact us to learn more about how to get started.

Max working temperature: 1500°C

208/220V single phase for all the model except 1500°C-161622 & 1500°C-242424 (1500°C-161622 & 1500°C-242424 require three phases)

Excellent temperature uniformity

Control heating rates, dwells (time holds), and cooling rates with 30-segment easy-to-use PID programmable temperature controller Long-lasting high-temperature Silicon Carbide heating elements ensure the longest heating element life, best heat radiation properties at high temperatures, and easy exchange

Long-lasting high-temperature Silicon Carbide heating elements ensure the longest heating element life, best heat radiation properties at high temperatures, and easy exchange

Ceramic fiber board lining ensures energy efficiency

1600°C Degree Celsius High-Temperature Box Furnace (2910°F):

Laboratory Applications

The 1600°C high temperature furnace is equipped with a double shell design to ensure low outside furnace temperature. This makes it ideal for dental, laboratory, universities, and any production scale applications. These furnaces are designed for accurate temperature control, excellent temperature uniformity, long lasting performance, and safe operations. The temperature ranges up to 1600°C and operate with 208/240V.

1600°C Box Furnace Features:

Max working temperature: 1600°C

30 Segment Easy Use Programmable Temperature Controller

High Performance Ceramic Fiber Board Lining

High Quality 1600°C 6/12mm Molybdenum Disilicide (MoSi2) Heating Elements

Fast Heat Up and Energy Efficiency

Double Shell Design to Ensure Low Outside Furnace Temperature

Over temperature Protection: The Furnace will automatically shut off if the Operating Temperature exceeds the pre-set Max. Operating Temperature

Control Console Displays Power Output, Working Voltage and Current

Long Life B Type Thermocouple

Most models are in stock for quick delivery

1700°C Degree Celsius High-Temperature Industrial Furnace (3090°F):-

Laboratory Application

Box furnaces come with a double-shell design to ensure a low outside surface temperature. A 30-segment easy-to-use, programmable temperature controller allows for precise temperature control. Accurate temperature control and uniformity makes the ST-1700°C box furnace is an ideal choice for dental, laboratory, university, and production applications. The furnace delivers a maximum working temperature up to 1700°C while operating with 208/240V.

1700°C Box Furnace Features

- Max working temperature: 1700°C

- 30 segment easy-to-use programmable temperature controller

- High-performance ceramic fiber board lining

- high-quality 1700°C 6mm/12mm Molybdenum Disilicide (MoSi2) heating elements

- Fast heat up and energy efficiency

- Double-shell design ensures low outside furnace temperature

- Automatic oven shut off if operating temperature exceeds pre-set maximum temperature

- Control console displays power output, working voltage, and current

- Long-lasting B-type thermocouple

- In-stock availability of most models allow for quick delivery

- One year limited warranty on all electronic parts

1800°C Degree Celsius High-Temperature Industrial Furnace (3090°F):-

Laboratory Application

With a Honeywell Temperate controller, the 1800°C high-temperature Box furnace offers the temperature range, consistency, and control needed to match even the most exacting lab or production processes. The furnace’s double shell design ensures low outside furnace temperature while its high-performance fiberboard lining delivers fast heat and uniform energy efficiency.

1800°C Box Furnace Features

- Eurotherm Temperature Controller

- High Quality 1800°C 6mm/12mm Molybdenum Disilicide (MoSi2) Heating Elements

- High Performance Ceramic Fiber Board Lining

- Fast Heat Up and Energy Efficiency

- Double Shell Design to Ensure Low Outside Furnace Temperature

- Control Console Displays Power Output, Working Voltage and Current

- Thermocouple: Pt20Rh/Pt40Rh, (Platinum – Rhodium)

- Most models are in stock for quick delivery

- One Year Limited Warranty on All Electronic Parts

A. Muffle Furnaces & High Temperature Box Furnaces:

1200°C Degree Celsius High-Temperature Muffle Furnace (2190°F)

The 1200°C Muffle Furnace’s double-shell design ensures low outside furnace temperature. Use this high-temperature muffle furnace for laboratory, universities, and any small production scale applications. Muffle furnaces deliver accurate temperature control, excellent temperature uniformity, long-lasting performance, and safe operations. The temperature ranges up to 1200°C and operate with 208/240V.

1200°C Box Furnace Features

- Max working temperature: 1200C

- 208/220V single phase for all the model except 1200°C-161622 & 1200°C-242424 ( 1200°C-161622 & 1200°C-242424 require three phases)

- Excellent temperature uniformity

- Control heating rates, dwells (time holds), and cooling rates with 30 Segment easy-to-use PID programmable temperature controller

- The unique configuration of heating elements design ensure the longest heating element life, best heat radiation properties, and minimum distortion of heating elements at a high temperature

- Ceramic fiber board lining ensures energy efficiency

- Long-lasting platinum/rhodium S-type thermocouple

- Safety interlock system shuts off power when furnace door open

- One year limited warranty on all electronic parts

- Standard models availability all.

Customizable high temperature laboratory muffle furnaces manufactured to meet your exact specifications is the leading manufacturer of custom high temperature muffle furnaces. All muffle furnace models provide excellent temperature control and uniformity, as well as superior energy efficiency. Each lab furnace can be customized to meet your exact specifications. Reduce costs of laboratory and small-scale production environments by using a customized high temperature furnace. Our lab furnace model specifications include (but are not limited to):

Muffle Furnace Specifications:

- 1200°C to 1800°C Maximum Operating Temperatures

- Chamber Dimensions up to 36” x 36” x 36” • 30 Segment PID Temperature Controller

- Quick Heat-Up and Cool-Down

- Excellent Temperature Accuracy and Uniformity

- Energy-Efficient Ceramic Fiber Insulation

- Double-Shell Design to Ensure Low Outside Temperature

- Automatic Shut-Off Safety Feature

- One Year Limited Warranty on Electronic Parts

B.MUFFLE FURNACE:

Laboratory use muffle furnace 1000°C 1200°C 1400°C & 1700°C

Muffle Furnace is box type heat treatment equipment used to change physical properties of samples at very high temperature; for example 1100°C, 1200°C, 1300°C, 1600°C and 1700°C. These laboratory furnaces are widely used in scientific experiments in physics lab, rice laboratories, steel and paint industries, biotech companies and small industrial production etc. Their major applications include general laboratory testing, annealing, ash determination, coal analysis, leaves carbonization and lime calcination etc.

We are leading muffle furnace manufacturers and suppliers in India. Our company makes these machines in various temperature ranges and chamber sizes. Each unit is made with rugged construction and equipped with easy to use controller system and safety devices. Standard models of our muffle furnaces come with maximum temperature range 1200°C, 1400°C, 1700°C and 1800°C.

Commonly used in laboratories, muffle furnace used for testing attributes of different materials at accurate as well as extremely high temperature. Also known as retort furnace, it comprises of vented heating chamber, temperature controller and safety door switch for operator safety. We are leading muffle furnace manufacturers in Odisha, India and deal in high-quality furnaces useful for a variety of purposes.

We deal in a variety of laboratory muffle furnace units, which are utilized in general purpose heating in laboratories, ashing tests on wool, rubber, fibers or fabrics, heat treatment requirements for gears and various research facilities in chemistry and physics. Dealing in furnaces suitable to work in temperature ranging from 800°C to 1800°C, we provide both readymade (ready stock) and customized muffle furnace systems to our customers worldwide. Being acting as a leading muffle furnace supplier in India, we ensure to offer the premium quality of muffle furnace to our all India customers at reasonable prices with assurance of timely delivery.

Detailed Description

- Temperature range: In muffle furnace there is maximum temperature range and continuous working temperature range. Our standard models are made with maximum temperatures 1100°C and 1400°C with working temperatures 1000°C and 1300° respectively.

- Heating Element: In muffle furnace 1100°C imported Kanthal A-1 resistive wire heating elements are used; while in 1400°C high temperature muffle furnaces, we use silicon carbide rods and MoSi2 (Molybdenum Disilicide) for 1600°C, and 1800°C.

- Heating Zone: The heating zone is the most crucial part of any muffle furnace. For 1100°C machine we make heating chamber of ceramic fiber board and for 1400°C Ceramic Zirconium board is used. High density Ceramic fiber blanket is used as insulation to keep the outer surface at minimum temperature.

- Controller: As standard microprocessor based PID temperature controller is fitted in each muffle furnace; in addition, we also use programmable profile temperature controller having 30 steps for ramp rate and soak time. These controllers feature excellent accuracy during the entire cycle and also keep displaying set value (SV) and process value (PV).

- Construction: These laboratory furnaces are built on a thick steel frame. Outer cabinet is usually made of powder coated cold roll sheet. We also make GMP muffle furnaces with all stainless steel 304 grade sheets.

- Optional Accessories: We also equip your programmable muffle furnace with choice of accessories to meet specific requirement of our clients. These accessories are PLC based HMI controller with data logging and PID controller with RS232 computer interface. Steel tong and gloves are standard accessories and supplied with every muffle furnace.

Features & Benefits

- Available in 1100°C, 1400°C, 1600°C & 1800°C temperature

- Programmable (profile) temperature controller

- Excellent temperature accuracy & uniformity

- Imported heating elements

- Rugged construction for long run

- Fitted with safety devices

- Customization as per user requirement

Muffle Furnace Applications:

| Ignition tests | Gravimetric analysis |

| Heat treating steel parts and Gears | Heat treating Gears |

| Coal sampling | Quench testing |

| Organic and inorganic ashing | Research facilities in chemistry |

| Chemical analysis | Annealing loss determination |

| soils & aggregates cement Testing | Development of coatings and ceramics |

| Glass blowing lab | Rice laboratory |

| Plastic tensile strength test | Stoneware samples firing |

Features

| Sturdy construction for long term use | Compact in design and space saving |

| Available with 800°C to 1800°C temperature | Safe and trouble free performance |

| Microprocessor PID controller | Over temperature and short circuit breaker |

| High ceramic fiber blanket and board insulation | Ventilation or chimney at the back |

| Only branded heating elements are used | Uniform heating inside chamber |

| CE marked | Comply to DIN and ASTM standards |

Safety Features

These muffle furnaces are microprocessor controlled programmable muffle furnaces that offer easy and safe operation even at high temperature. These systems are designed with your safety in mind. Multi-layered insulation keeps external surfaces (cabinet) cool to the touch. Door safety switch (optional accessory) stops power to heating elements when door is opened.

Standard Inner Chamber Sizes

| Dimension (Inches) | Volume (Liter) |

|---|---|

| 4x4x9 | 2 |

| 5x5x10 | 4 |

| 5x5x12 | 5 |

| 6x6x12 | 7 |

| 8x8x12 | 13 |

| 12x12x12 | 28 |

| 18x18x18 | 96 |

Muffle Furnace Accessories

Chart Recorder

Tongs

Heating Element

Gloves

Quick Actions

Products List

- Laboratory Plasticware

- Laboratory Glassware

- Laboratory Chemicals

- High Pressure Autoclaves Reactors

- S.S High Temp Reactor

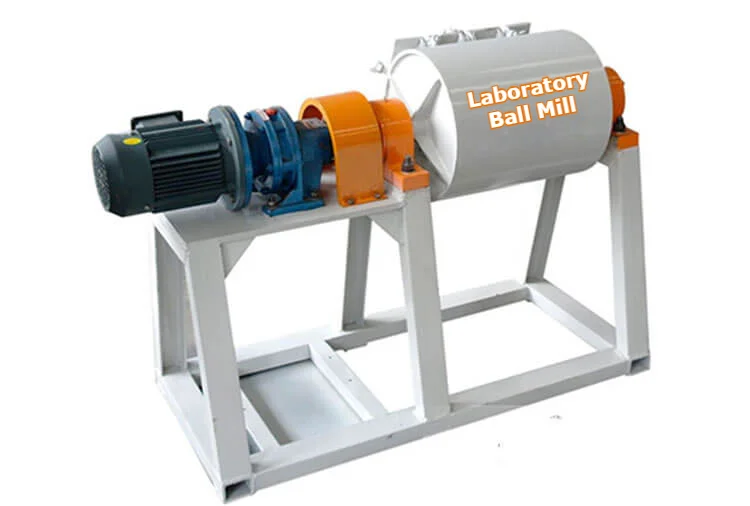

- Ball Mill

- Hot Air Oven

- High Temperature Furnaces

- Heating Mantle

- Oil Bath

- Water Bath

- Silicon Carbide Heating Elements (SIC)

- Silicon Carbide Crucibles

- Hot Plate

- Hot Plate With Magnetic Stirrer

- PH Meter

- TDS Meter

- Graphite Crucibles

- 99% Alumina Crucibles, Boat, Rod, Dish, Tray, Plate & Tubes etc

- Graphite Rod

- Overhead Stirrers

- Metal Product

- AODD Pump

- ETP/STP Water Treatment Plant

- Hydraulic Pellet Press

Get a Quote

Interested in this product? Contact us for pricing and availability.