Silicon Carbide Heating Elements(SIC)

- Home

- Products

- Silicon Carbide Heating Elements(SIC)

We supply of Silicon Carbide Heating Elements (silicon carbide heaters ) that are known under the tradename of “Alpha Rod, Alpha Ultra Rod, Alpha Ultra Spiral”

The Alpha Rod elements are tubes with thick walls and are made from high resistance silicon carbide (heaters) elements. The element tubes consist of a central heating section referred to as a hot zone and two terminal sections called cold ends. The cold ends are infused with silicon metal to bring down their resistance and operating them at a lower temperature. The extreme ends of the elements are coated with aluminum contact surface with low resistance to which the electrical connections are made with braided aluminum straps. Elements are described by giving the- overall length, the heating section length, the diameter and the resistance.

High-Performance SIC Heaters from AMRI TECH

Due to their high density of 2.4gms/cc (or more), the Alpha Rod Elements are designed to give superior performance. This gives the element exceptional characteristics and additional strength.

Special Surface Coatings

Various kinds of special surface coatings are provided onto the Alpha SiC rods. These vary from glass coatings to Chemical Vapor Deposition (CVD) coatings depending on the area of application. We provide different coatings for assaying furnaces, coatings to be employed in very high vacuum applications and coating to be employed in reducing atmospheres.

Do get in touch with us and let us know about your applications and atmospheres in which you wish to use the heaters and we will suggest the right surface coating for the application.

Very High Operating Temperatures

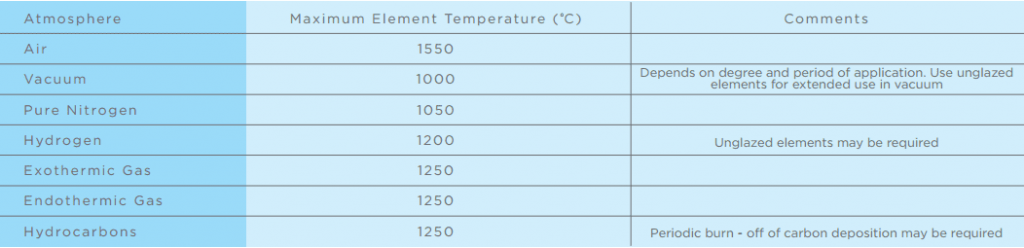

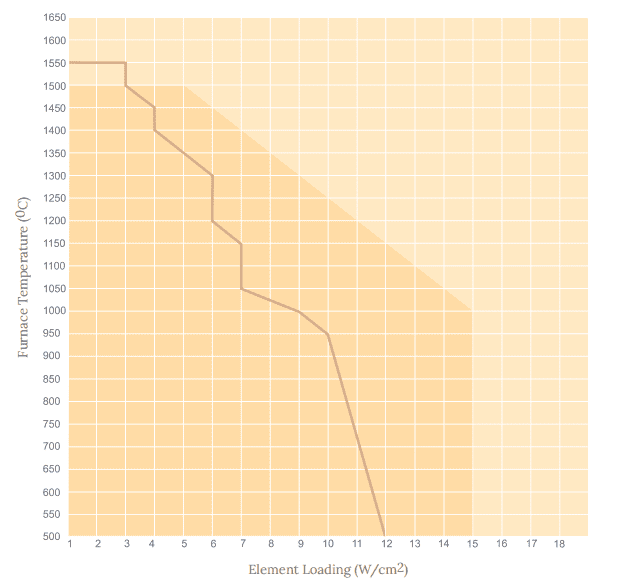

The operating temperature of the Alpha Rod Elements can go up to 1550°C in an oxidizing atmosphere, or inert gas atmospheres of argon or helium. in a reducing atmosphere, the maximum obtainable operating temperature is 1350°C.

Characteristics of SIC – Alpha Rod Elements

- The Alpha Rod Heating element is a linear type resistance heater that converts electrical energy to heat energy (Joule’s Law W=I2R). W=power in watts, I=current in amperes, R=resistance in Ω.

- The heating elements are self-bonded, for the lattice structure or bonds that hold the elements together that are formed by recrystallizing the silicon carbide at high temperatures.

- The elements are made from green(beta) silicon carbide which is an excess electron type semiconductor.

- It is difficult to measure the resistance of a silicon carbide element at room temperature. This is due to the presence of minor impurities, contact resistance, and self-healing.

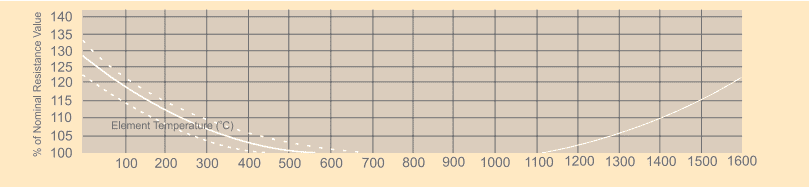

- Silicon carbide also has a characteristic negative resistance temperature from room temperature to approximately 800°C. It turns positive at this point and remains so throughout its operating temperature range.

- A typical resistance-temperature characteristic curve of a silicon carbide heating element Nominal element resistance is measured at a standard calibrating temperature of 1050°C.

Service Life

- Operating temperature.

- Electrical Loading – Usually Expressed in watts per square centimeter of element radiating surface.

- The type of Atmosphere.

- Type of operation

- Operating and Maintenance Techniques.

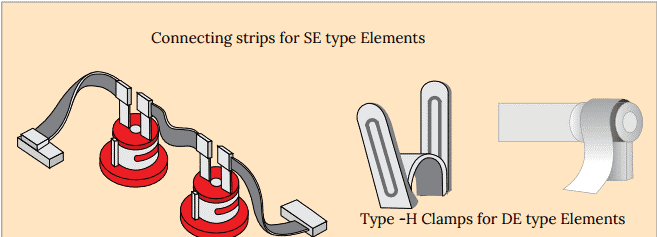

Mounting of alpha rod heaters

There are no restrictions on the mounting positions of Silicon Carbide Heating Elements. Horizontal and vertical positions are the most common positions. The Heating elements must be mounted with extreme caution to ensure that the elements are not mounted in tension. There should be adequate allowances provided for the furnace and elements to expand and contract without any hinderance. When the elements are mounted vertically, it must be made sure that they are supported on the lower end by electrically insulated supports. It is ideal for the Silicon Carbide Elements to have their heating sections centered in the furnace chamber so that no portion of the heating section extends into the furnace wall. For heat to be radiated properly and the temperature to be maintained, a conical or truncated cone-shaped recess inch deep is provided on each interior wall where the element passes through.

Ordering with AMRI TECH

Alpha Rod Elements are specified as follows

Diameter / Hot zone length / Overall length / Nominal resistance.

Ordering sort of the alpha ultra elements are specified as follows

Diameter / Hot zone length / Overall lengths / Nominal resistance.

Ultra-Spiral Type Double End elements can also be provided with offset Hot zones i.e., unequal cold end lengths and also split hot zones for central support in exceptionally long hot zones. Please specify your exact requirements. Preferably with drawings while ordering. Closer tolerances on-resistance can be supplied at Special rates.

Electrical Characteristics of ‘Ultra-Spiral /Alpha Rod Elements

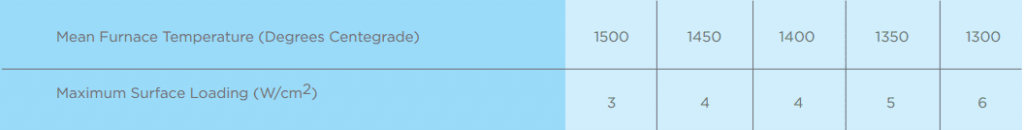

The resistance of Ultra-Spiral / Alpha SiC rod Element varies with temperature as detailed in the below table. From relatively high value at room temperature, it falls to a minimum at about 800℃ and then gradually rises to its maximum operating temperature.

The resistance value at 1400℃ will approximately be 10% more than its value at 800℃. The voltage across the element and the current passing through it should be measured at about 800℃ to determine the resistance (V=IR)

Operating Temperatures

Alpha Ultra Spiral /Alpha Rod elements can operate in air(oxidizing) at the furnace temperature of up to 1550℃. Elements can also be used in a reducing or neutral atmosphere but at lower temperatures. The recommended operating temperatures for Ultra Spiral /Alpha Rod Elements in different process atmospheres are as follows.

(Note that element temperatures are indicated and that these may be Considerably higher than the furnace temperature)

Resistance/Temperature Characteristics

Power Input

A variable voltage source is necessary to provide power input to the heating elements to offset the drop in rating due to the aging of the elements with use. A transformer (tapping or continuously variable) or a thyristor drive would serve the purpose. However, it is recommended that a 100% voltage reserve be provided to ensure the maximum life from the heating elements. In the case of a stepped output tapping transformer, it should be ensured that adequate taps are provided. It is recommended that a minimum of 8 Stepped outputs or taps be provided to ensure that the elements are not drastically overloaded While changing from one tap to the next higher one.

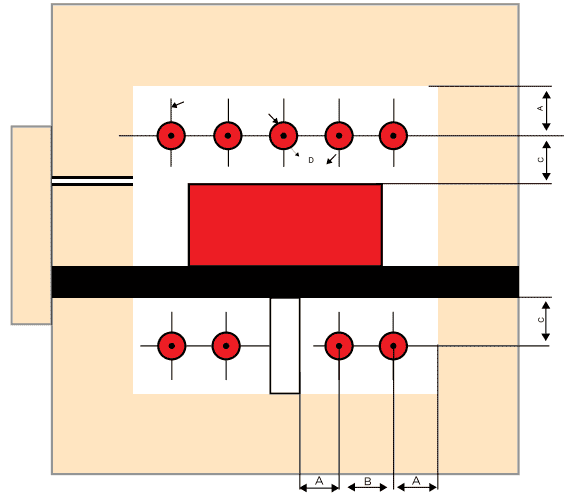

Element Spacing

Alpha Rod/alpha ultra spiral should be spaced at a minimum of 1 diameter between element centers and the refractory lining. A clearance of at least 2.5 diameters, should be allowed between the element centers and the wall, but it may be necessary to increase this if uniformity of heating is required, especially if the distance between adjacent elements is large.

A = ( 1.5 x D) = Minimum spacing between component centre & adjacent refractory

B = ( 2.5 x D) = Minimum spacing between adjacent element centres

C = ( 1.5 x D) = Minimum spacing between component centers & hearth plates or work

D = component Diameter

Products List

- Laboratory Plasticware

- Laboratory Glassware

- Laboratory chemicals

- High pressure autoclaves reactors

- S.S High temp Reactor

- Ball mill

- Hot air oven

- High Temperature Furnaces

- Heating mantle

- Oil bath

- Water bath

- Silicon Carbide Heating Elements(SIC)

- Silicon carbide crucibles

- Hot plate

- Hot plate with magnetic stirrer

- PH meter

- TDS meter

- Graphite Crucibles

- 99% Alumina crucibles ,Boat ,Rod, dish, tray, plate &Tubes etc

- Graphite Rod

- Overhead Stirrers

- Metal Product

- AODD PUMP

- ETP/STP water treatment plant

- Hydraulic Pellet Press